RISK

MANAGEMENT:

RISK

MANAGEMENT

Construction projects are

inherently risky. RSG knows that each project will have risks

associated with safety, cost, quality, schedule, environmental

compliance, and operations. Our approach to construction risk

management is to plan and prepare contingency plans. Each Risk

Management Plan will include a description of each probable risk,

probability of occurrence, mitigation measures, an action plan for each

mitigation measure, the methodology to measure the effectiveness of

each measure, and the frequency of review and updating. The status of

each Risk Management Plan will be included in the Project Construction

Manager’s monthly project status report to the Client’s

representative.

Our detailed perspectives of discernible risks that are required to

ensure the success of the project are as follows:

- Public Safety

- Environmental Safety

- Owner Cost

- Schedule Impacts

- Material and Installation Defects

- Worker Safety

- Public Access & Convenience

As the CM, the RSG Team as a whole must examine each task and determine

the possible risks in each of these areas and work with the

Client’s staff and the Contractor to eliminate or reduce the

discernible risk in each area.

|

|

CONSTRUCTION

INSPECTION

RSG’s inspection procedures

include detailed review and analysis of shop drawings, engineering

drawings, and approval of contractor’s pay requisition. We

advise the contractor of the various change orders and field revision

as necessary per project or Client requirements.

We prepare detailed plan reports, final approved plans, specifications

and construction estimates. Our staff provides detailed progress

reports throughout the life of the project.

|

|

QUALITY

ASSURANCE

In accordance with the

Client approved QC/QA plan, inspect, monitor, and document the

activities of the contractor, subcontractors, and suppliers to ensure

compliance with the requirements of contract documents.

- Review the contractor’s

quality control plan Meet with contractor to define and interface

Client quality program to contractors program.

- Define quality roles and staff

assignments as necessary.

- Establish processes to allow for

proper implementation of the quality plan.

- Develop written procedures to

implement the approved Client QC/QA plan in the field. Generate a

comprehensive QC/QA matrix for each of the specifications.

- Implement the approved project QA

procedures.

|

|

CLAIMS

AVOIDANCE

The RSG team’s approach to

claims avoidance begins with preventing claims by assuring the

development of properly conceived contractual terms that clearly assign

risks to the parties best suited to deal with them, and complete,

coordinated design drawings and specifications detailing the technical

and operational requirements of the Contract Documents. Claims

avoidance actions during construction should entail:

- Get an accurate baseline schedule

and updates. The baseline schedule will help discourage submittal of

time-related claims by accurately identifying critical work items and

quantifying resource requirements planned for each item of work.

- Carefully monitor and rapidly

respond to correspondence, submittals, RFIs, and RFSs to identify

potential problems and minimize the Contractor’s opportunities to

claim delays.

- Pro-actively manage the

procurement, fabrication, quality assurance and delivery of Client

pre-purchased equipment and material.

- Maintain open communication and an

open mind when listening to the Contractor’s ideas or complaints

and work with the Contractor to solve problems early.

- Participate proactively in

“partnering” with the Contractor during the term of the

contract.

- Maintain a “tough but

fair” attitude with the Contractor to assure that the Client is

not taken advantage of and the Contractor is treated fairly,

particularly on change orders issues.

- Be as knowledgeable as the

Contractor as to the “history” of the project and maintain

thorough and comprehensive records.

- Maintain constant job

“presence” at the worksite and in the offices to allow

constant observation of the work and quick response to problems.

|

|

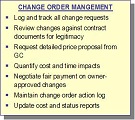

CHANGE MANAGEMENT

The Construction Manager is

responsible for managing the change management process in conformance

with the requirements in the Contract Documents, leading the

negotiation of cost and/or time impacts, and providing recommendations

for the disposition of Change Requests. The Office/Field Engineer

assists the Project Construction Manager in managing the change

process, maintains all change request files, and records of

negotiations and maintains the Change Log. The Project engineer

will support the preparation of owner requested changes and review of

all technical Change Requests.

|

|

NEGOTIATION

of CHANGES

The RSG team’s approach to

change request negotiations is to negotiate fairly and openly using the

Contract Documents as the basis of any settlement. The goal should be

to answer the change request within one payment cycle. The

construction Contract Documents will include requirements for the

necessary documentation that must be used and accompany all change

requests. |

|

|

|

|

|

|

|